Sodium hyaluronate (SH) is produced through fermentation using Streptococcus equi subsp. zooepidemicus, with glucose, yeast extract, and peptone as the culture medium. It is the sodium salt of glycosaminoglycan, composed of disaccharide units of D-glucuronic acid and N-acetyl-D-glucosamine, forming a linear macromolecular polysaccharide. Sodium hyaluronate, with the chemical formula (C14H20NO11Na)n, is a naturally occurring substance in the human body. It is a type of glucuronic acid that lacks species specificity and is widely present in tissues and organs such as the placenta, amniotic fluid, lens, articular cartilage, and dermal layers of the skin. It is distributed in the cytoplasm and extracellular matrix, playing a role in lubricating and nourishing the cells and organelles within.

Sodium hyaluronate is the gold standard for moisturizing ingredients in skincare products. It leads the skincare market, becoming a benchmark ingredient frequently mentioned and demanded by consumers when discussing innovation, trends, and efficacy. Sodium hyaluronate is the sodium salt form of hyaluronic acid, a high-molecular-weight linear polysaccharide composed of repeating disaccharide units of N-acetylglucosamine and D-glucuronic acid. It is widely found in the extracellular matrix of connective tissues in animals and humans.

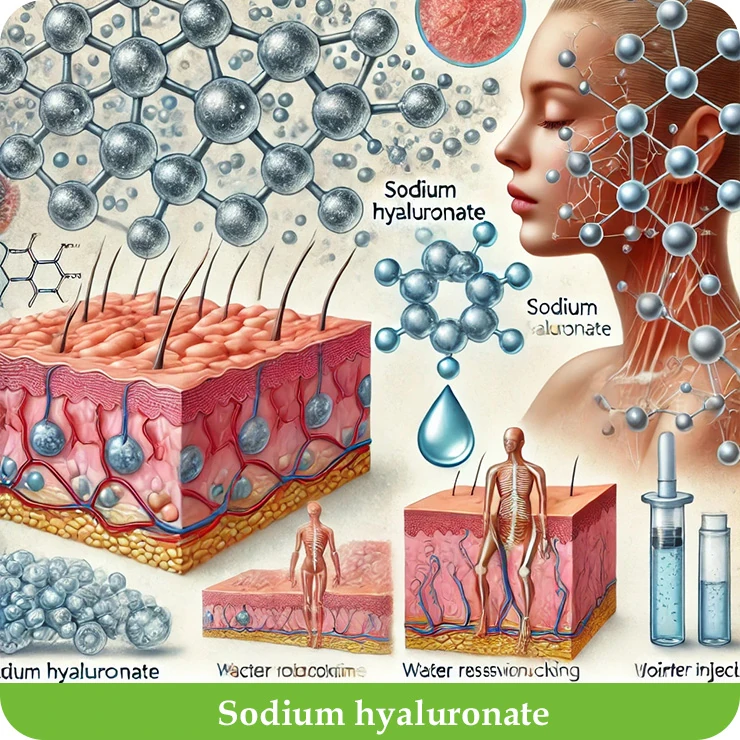

In an aqueous solution, its highly extended and irregularly coiled configuration allows it to occupy a large area, and the entanglement of its molecular chains forms a continuous network structure. This makes sodium hyaluronate act like a “molecular sponge,” capable of absorbing and retaining water many times its weight. It is widely used in medicine, cosmetics, and health foods. Upon entering the body, sodium hyaluronate can be hydrolyzed into hyaluronic acid, providing moisturizing, soothing, anti-inflammatory, repair, elasticity-enhancing, and anti-wrinkle effects for the skin.

Hyaluronic Acid

Hyaluronic acid, or HA, carries negative ions and is hydrophilic, meaning it can absorb much water. The spaces between collagen fibers in the dermis are primarily filled with water retained by hyaluronic acid. Its molecular structure can hold over 500 times its weight in water. However, due to its large molecular size, hyaluronic acid cannot penetrate the skin to reach the dermis, so using it topically for wrinkle removal is not possible. Nonetheless, it is an excellent moisturizing ingredient that can reduce fine lines caused by skin dryness.

Hydrolyzed Hyaluronic Acid

Hydrolyzed hyaluronic acid is produced by enzymatically breaking down high-molecular-weight hyaluronic acid into smaller molecules to improve its permeability. Unlike regular hyaluronic acid, which has a molecular weight of around 500,000 to 2,000,000 Daltons (Da), hydrolyzed hyaluronic acid typically has a molecular weight below 10,000 Da.

Mechanism of Action

Sodium hyaluronate acts as a tissue lubricant and is believed to play an important role in regulating interactions between adjacent tissues. In water, it forms a viscoelastic solution. The high viscosity of the solution provides mechanical protection to tissues (such as the iris and retina) and cell layers (such as the corneal endothelium and epithelium). The elasticity of the solution helps absorb mechanical stress and provides a protective cushion for tissues. In wound healing, it is thought to act as a protective transport medium, delivering peptide growth factors and other structural proteins to the site of action. Enzymatic degradation then releases active proteins to promote tissue repair.

Common types of sodium hyaluronate include:

- Oligomeric sodium hyaluronate (molecular weight less than 10,000 Da);

- Low molecular weight sodium hyaluronate (molecular weight between 10,000 Da and 1,000,000 Da);

- Medium molecular weight sodium hyaluronate (molecular weight between 1,000,000 Da and 1,800,000 Da);

- High molecular weight sodium hyaluronate (molecular weight >1,800,000 Da).

Production Methods of Sodium Hyaluronate

- Animal Tissue Extraction

The main raw materials are chicken combs and bovine vitreous humor. The raw materials are defatted and dehydrated using acetone or ethanol, soaked in distilled water, filtered, and then treated with sodium chloride solution and chloroform. After adding trypsin and incubating, a mixture is obtained, which is then purified using ion exchange to obtain refined hyaluronic acid. This method has a very low extraction rate, only about 1%, and the separation process is complex, making the cost of hyaluronic acid high (up to $5,000/kg), and limiting its widespread use in cosmetics and industrial products. - Microbial Fermentation

Glucose is used as a carbon source in the fermentation medium, and after 48 hours of fermentation, the resulting broth is filtered to remove mycelium and impurities. High-purity hyaluronic acid is then obtained through simple operations such as alcohol precipitation. The key to microbial fermentation lies in strain selection. - Chemical Synthesis

This method involves using polysaccharide polymerization reactions. First, “hyaluronic acid oxazoline derivatives” are synthesized from polysaccharide polymers, and then a water-hydrolyzing enzyme is added to produce a compound of the derivative and enzyme. Finally, the enzyme is removed in a high-temperature reaction, yielding hyaluronic acid.

Functions

- Improving Drug Efficacy

HA is a major component of the extracellular matrix, vitreous humor, and synovial fluid in joints, playing roles in water retention, maintaining extracellular space, regulating osmotic pressure, lubricating, and promoting cell repair. As a carrier in eye drops, HA increases the viscosity of the solution, prolonging the time the drug stays on the eye surface, enhancing bioavailability, and reducing irritation. - Auxiliary Treatment

Sodium hyaluronate can be injected directly into joint cavities as a lubricant for treating arthritis. As a moisturizing agent, it plays a critical role in skin hydration, giving the skin a smooth and delicate appearance. The moisture-retaining capacity of sodium hyaluronate makes it suitable for different humidity levels and skin care needs throughout the seasons. - Anti-Wrinkle

The moisture level in the skin is closely related to hyaluronic acid content. As we age, the amount of hyaluronic acid in the skin decreases, leading to reduced moisture retention and the formation of wrinkles. Sodium hyaluronate solution has strong viscoelastic and lubricating properties, forming a moisture-locking breathable film on the skin surface, keeping it hydrated and radiant. - Film-Forming and Lubrication

Sodium hyaluronate, as a high-molecular-weight polymer, offers a smooth feel when applied and forms a breathable film on the skin, protecting it from external pollutants like bacteria and dust. - Sun Protection and Skin Repair

Sodium hyaluronate helps eliminate reactive oxygen species (ROS) produced by UV radiation, protecting the skin from UV damage. Additionally, it promotes the proliferation and differentiation of epidermal cells, accelerating skin regeneration at injury sites.

Applications of Sodium Hyaluronate in Cosmetics

- Emulsifying Agent

Sodium hyaluronate combined with phospholipids forms an emulsifying agent. Without any other emulsifier, adding sodium hyaluronate and phospholipids to oil and water mixtures results in a stable emulsion with moisturizing properties, making it an ideal natural emulsifier. - Thickening Agent

Sodium hyaluronate combined with polyethylene oxide (PEO) creates an excellent thickening agent with superior moisturizing capabilities. It is suitable for making creams, lotions, gels, and semi-transparent elastic gels, such as shaving gels and sunscreens. - Fragrance Fixative

Sodium hyaluronate can encapsulate various substances, acting as a fixative in fragranced products. When combined with fragrances, it slows down the evaporation rate, extending the duration of the scent.

Pharmacological Effects

Sodium hyaluronate is widely distributed in animal and human tissues. It has high viscoelasticity and contouring ability, making it an auxiliary agent for ophthalmic surgeries. Injecting the solution into the anterior chamber helps maintain depth, facilitates operations, protects corneal endothelial cells, and reduces complications.

Different molecular weights of sodium hyaluronate are used for:

✔ Aesthetic procedures like micro-needling;

✔ Ophthalmic surgery as a viscoelastic agent;

✔ Intra-articular injections for joint treatments;

✔ Post-surgical anti-adhesion therapy;

✔ Enhancing endogenous HA synthesis;

✔ Moisturizing, anti-wrinkle, and nourishing cosmetic products;

✔ Eye drops;

✔ Low-molecular-weight sodium hyaluronate for oral supplements;

✔ Anti-tumor therapies;

✔ Wound healing;

✔ Modulating vascularization;

✔ Activating cellular immunity.